Last month we gave you an overview of our InPower Family Tree of Switching Products, and explained how they all share three design philosophy principles: consistency of operation, efficiency of design, and the flexible “smarts” to program them to fit the job. We discussed how those principles are incorporated into three major product branches designed to perform smart-switching tasks in different situations and conditions.

This month we are diving deeper to show you how:

- flexible these modules can be.

- these principles work in the real world.

- every product starts with the humble beginnings of the original and ever-practical VCM.

The Hero of Our Story: The VCM

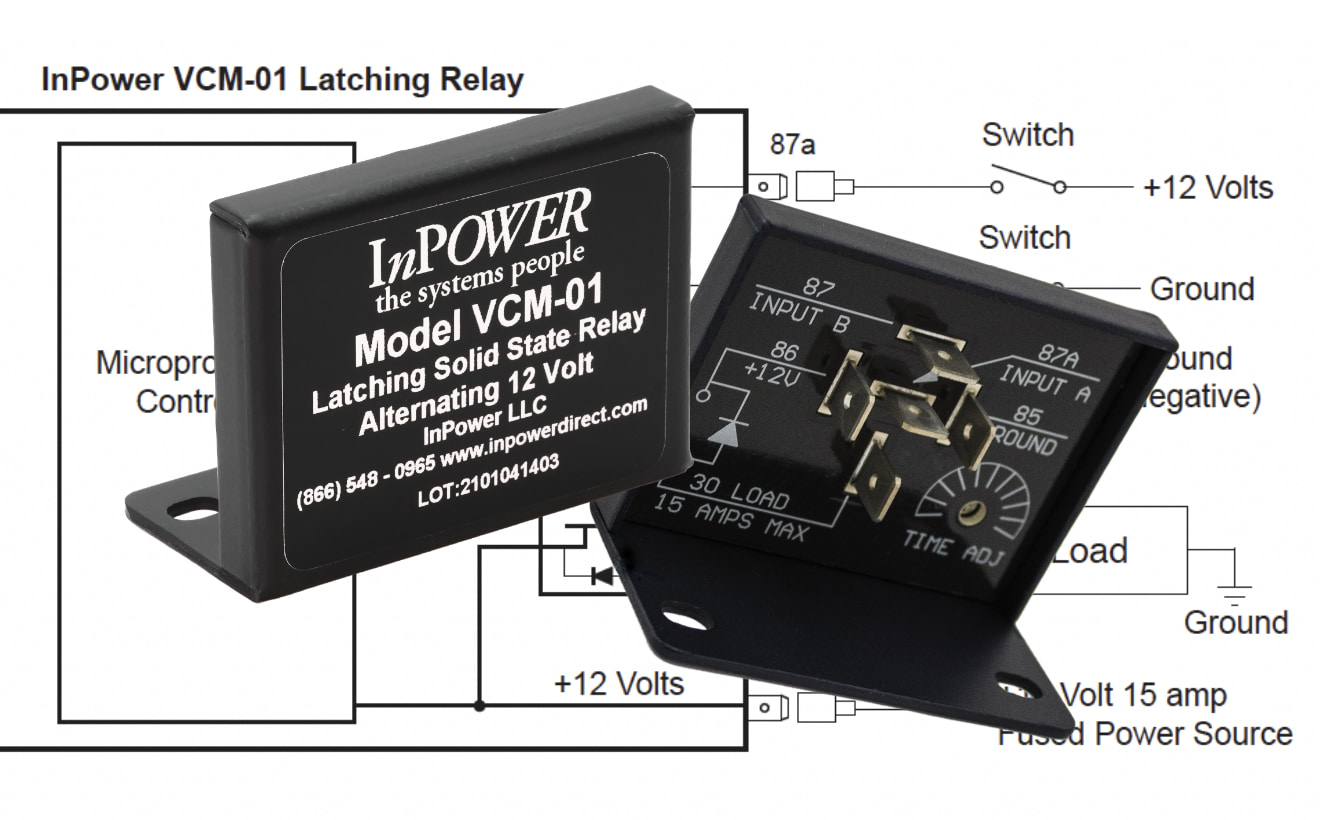

The VCM is, at heart, just a simple solid-state switching device with a 5-blade I/O pinout that looks a lot like other automotive relays have for many decades. One pin is your 12-volt power input, one is your output, and one provides the ground. The other two pins are where the module “listens” for signal inputs to tell them what to do—those signals are usually either a ground or a +12V signal. That’s where the similarities to normal relays end.

Instead of the coils, springs, and wires a normal relay has on the inside, the VCM has a programmable computer giving this one hardware design hundreds of possibilities. It’s an efficient and smart way to make a module.

In the 17 years we’ve made VCMs, we’ve written hundreds of programs to handle all sorts of applications requested by our customers. Some of these include:

- Timer delays for exit and entry lamps

- Custom signals to replace burned-out relay logic boards from old pinball machines

- A special relay to drive a “thumper” on a joystick control for a bucket lift

- Modules that respond to momentary signals, continuous signals, and even patterns of signals

- A custom program that responds in milliseconds to a light beam for a safety lockout

We could probably program a module to pulse out the lyrics to the Star Spangled Banner in Morse Code if a customer needed that (all of our modules are built at our Ohio facility, after all).

All joking aside, we even found a way to give some smarts to the classic electro-mechanical relay with our VCMR. Some applications require normally open or normally closed contacts, or they need the smarts of VCM but with the absolute signal isolation of a conventional relay. The VCMR gives everyone the best of both worlds.

This easy and flexible customization scales up to meet many other challenges of increasing complexity, power, or monitoring. It’s one set of design principles, applied at many different levels to meet your specific needs.

Contact us for more information about how our VCM series can simplify and improve your vehicles’ electrical systems.